How porcelain tile is made. Italian Edition!

Along with a small contingent of developers and designers, Context was recently a guest of Olympia Tile in the Emilia Romagna region of Italy – otherwise known as the home of Ferraris, Bolognese and Porcelain Tile!

Porcelain tile is the primary type of floor and wall tile that we use in the foyers, kitchens and bathrooms of our condominium suites. The tile is harder and more durable than ceramic or most natural stones and offers greater design flexibility with colours, textures and finishes. The purpose of the trip was to visit the factories and showrooms of the leading porcelain tile manufacturers and learn how the tile is made, view the new lines and assess trends that will be emerging in the market place.

Porcelain is made from raw materials such as clay based minerals, glass, feldspar, silica and quartz that are crushed together into a fine granular mix.

Once mixed, they are formed and pressed into the desired tile sizes and then briefly bisque fired (heated at a low temperature) to give it a semi hardened state. From here, the tiles are then glazed to give them the chosen appearance such as a natural stone look, colour, texture or graphic on the surface. In many cases this is done by large format laser printing on the surface of the tile.

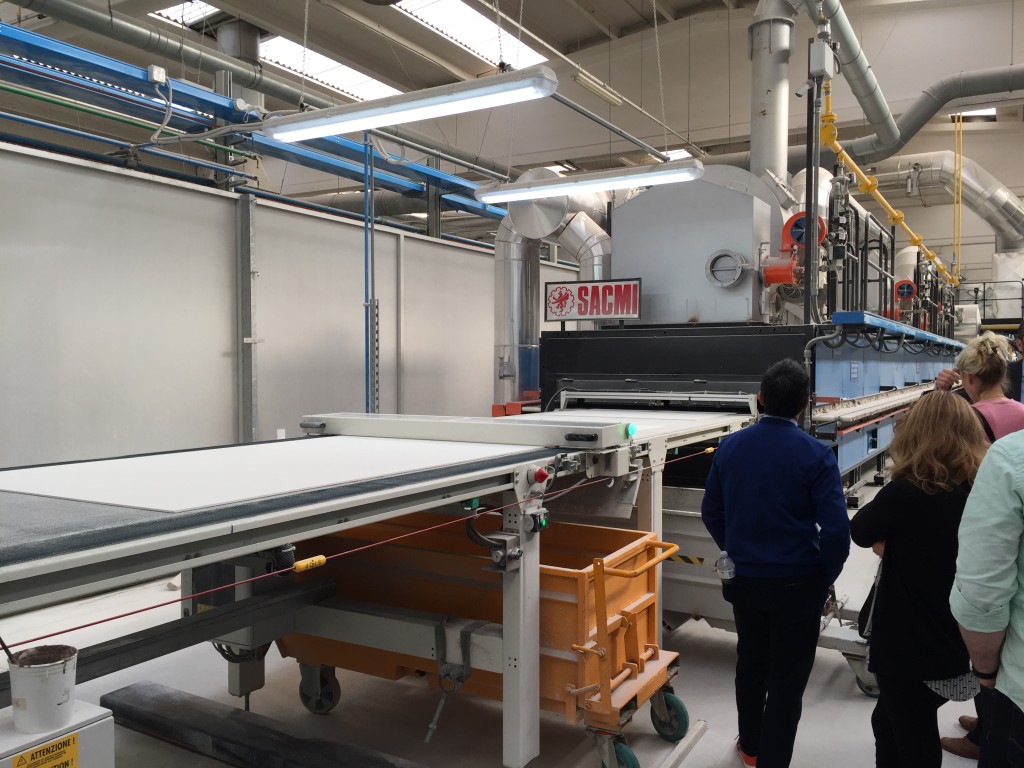

Once the design has been applied, the tiles are then sent into a large kiln (often several hundred feet long) to be fired at a variety of temperatures up to 1200 degrees Celsius. Upon exiting the kiln, the tiles begin their cooling process prior to being packaged, shipped across the Atlantic and installed in your kitchen and bathroom.

During the trip, two clear trends became apparent as the European market place is beginning to demand larger tile sizes and increased textures and graphic features. Traditionally, our market place was accustomed to 12” x 12” tiles that has more recently moved onto 12” x 24” and 24” x 24” as the preferred sizes. Increasingly, the sizes are growing to include 36” x 36”, 24” x 48”, and 48”” x 48” and larger. Additionally, porcelain slabs are now being produced in greater numbers and are overtaking natural stone slabs as counter top surfaces as well as custom wall slabs for fireplaces, bathrooms and feature walls.

A special grazie to Olympia Tile for their wonderful hospitality!